(Caroline Foty's first fountain pen was a 1970s Sheaffer No Nonsense that still writes perfectly. Since she discovered pens by independent makers, she wants "one of each, please" and wants to meet all the makers. Maybe you do, too. She lives in Baltimore with pens, cats, and all kinds of fiber arts supplies.)

Pens, you may know, are easier to haul around than serving trays and cutting boards.

Rich Paul was a woodworking hobbyist selling such ‘flat goods’ at craft shows in and around Pittsburgh, when a visiting friend insisted on bringing along a lathe and showing him how to make a pen. Despite having resisted the idea of adding another product to his portfolio, not to mention all the tools and materials it would require, Rich was immediately hooked by penmaking, even aside from the easier packing and hauling.

He started making kit pens, but found that craft shows were not a place many people bought pens, so he then tried vending them at shows for artists. When his friend Jim Hinze was teaching a kitless pen class at a pen turners association meeting, he watched a session and then “struggled through” making a first kitless pen. In 2019 he began selling his custom pens on Instagram, and was scheduled to go to the 2020 Atlanta Pen Show, which turned out to be the first show cancellation of the COVID lockdowns. In spite of these obstacles, the pens kept selling online.

Other than a short period during a temporary layoff, Rich is not a fulltime pen maker. He works for the local health department, managing a team of inspectors who review plans for food establishments. His intent is to do this until retirement and then just make pens. “Making pens is better than dealing with people all day, pens don’t talk back!” The way he relaxes at the end of the day is to eat dinner, take a nap in front of the TV, and then hit the shop.

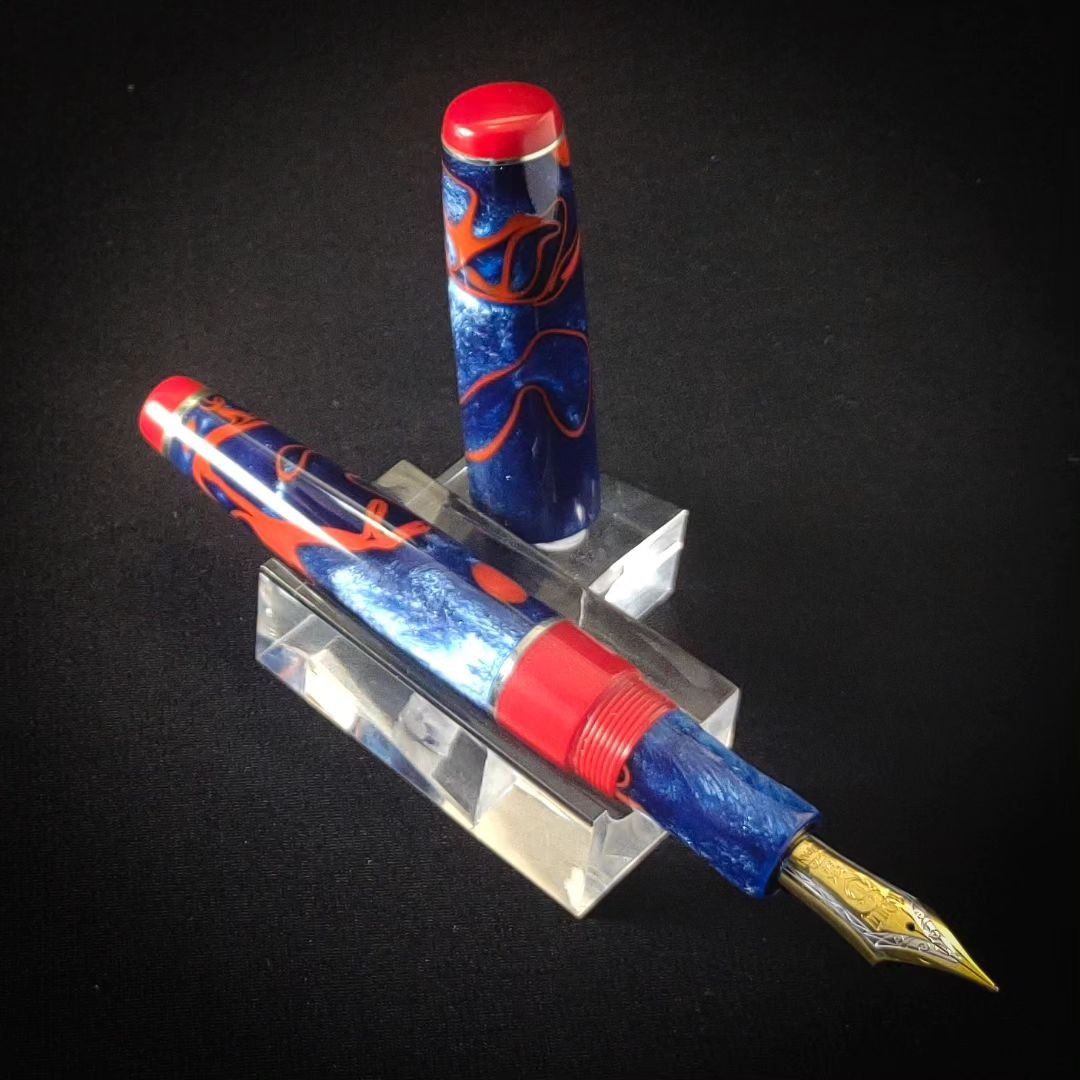

Rich has evolved a core lineup of a few pen models, and prefers classic styles to some of the more unusual things other makers are doing. “I’m not an artist, I use my pens at work and at shows.” His biggest source of inspiration is in the materials and the colors available for use with those classic models. “Anytime I get some new blanks, I grab one right away and go make a pen.” He recently made a pen with Fordite from a Jeep factory. And he is one of the few makers who makes many pens in the jewel-like but pricey Oparex material. “It was hard to work with at first, it’s very delicate, and in the beginning I made some expensive mistakes.” It’s rare than any of his Oparex pens stay in stock long enough to be seen at a show.

Despite the inspiration he derives from materials, Rich is not going to take up casting blanks. “It seems like people who get really good at making blanks end up making fewer pens. I want to keep making pens.” His twenty-five-year-old daughter, however, is interested in taking up blank making, and he plans to take her to visit Tim Crowe of Turnt Pen Company to get a lesson.

Like most pen makers, Rich cites community as one of the best things about being a pen maker, and the relationships that are formed among makers and customers. “When I was an outsider, I was accepted. The people I’ve met and the places I’ve gotten to go… the best part of doing this is seeing everyone at shows.”

Favorite pens also come from the penmaking community. The first big pen he bought for himself was a Hinze Pens Evancio, with a #8 Bock nib. At his first pen show, he met Carrick Ryan (Champion Turnings), who was only 13 at the time, and when he got home after the show he ordered a Champion pen.

His love of the community doesn’t mean, however, that he will share his most proprietary bit of data: where he gets the inserts to make his unique dip nib holders. When the Kakimori nibs began to become popular, he looked at the nib holders sold to go with them and found them “very minimalistic and plain,” and thought maybe he could improve on that. He bought a couple of them and chiseled them apart to get the inserts out, to do a proof of concept, and then worked to find a source for them. They are not just for Kakimori nibs, and can take most modern calligraphy nibs.

Even while sticking with classic styles, Rich feels that his pen making has evolved in less visible ways, finding better and more efficient ways to do the same thing. Accepting individual commissions is a way to keep fresh, and he tries to keep his commission queue to less than two months. If a customer has something specific in mind in terms of colors and materials, he will send them to a blank maker to work out the right material for their pen. While he has done some collaborations that have necessitated making a large number of the same pen under the pressure of a deadline, and would do it again, his personal preference is to get quickly to a finished pen and go on to make something different.

Getting quickly to a finished pen lets him get quickly to the satisfaction that comes from “people being so happy with something that you’ve made and maybe take for granted.”

Rich Paul’s work can be seen on his Instagram @rivercitypencompany, his website RiverCityPenCompany.com, and at shows in Philadelphia, Baltimore, DC, Orlando, San Francisco, Raleigh, and Ohio.

Enjoy reading The Pen Addict? Then consider becoming a member to receive additional weekly content, giveaways, and discounts in The Pen Addict shop. Plus, you support me and the site directly, for which I am very grateful.

Membership starts at just $5/month, with a discounted annual option available. To find out more about membership click here and join us!