(Caroline Foty's first fountain pen was a 1970s Sheaffer No Nonsense that still writes perfectly. Since she discovered pens by independent makers, she wants "one of each, please" and wants to meet all the makers. Maybe you do, too. She lives in Baltimore with pens, cats, and all kinds of fiber arts supplies.)

You may have wondered – how did Jonathon Brooks actually get started in the pen world? If you guessed date night, you win.

“It was a date night with Shea. My grandfather did a lot of woodworking - he passed away when I was ten, but I remember him doing lathe work. Shea and I did a weekend lesson on making kit pens.” The teacher of the lessons was also a pastor and ultimately officiated when date nights progressed to a wedding.

Brooks wasn’t an artist, or an obsessive writer, but he had a rollerball pen he used all through high school. “I found one I really loved, and I kept it.” With pen turning know-how came a new point of view on that pen. “I built my own pen based on it. I was between jobs - I saw a challenge in pen making, and decided to pursue it.” At the time (2008), kit pens used store bought acrylic and wood blanks. “Every blank looked the same. I got bored with them within a year.” Only a few people were casting pen materials at that time, so he taught himself to cast, beginning with polyester resin. When he posted a pen from his material on a forum on the International Association of Penturners website, he was bombarded with questions about where the material came from. Within months, he was able to take the pen and materials business full-time, which dovetailed nicely with the decision to become a stay at home dad.

His first customers weren’t other pen makers, but online vendors like Exotic Blanks. “I got in at the forefront of the maker boom. Custom pens weren’t really a thing - Brian Gray (Edison) was someone everybody looked up to.” He quickly decided, however, to sell blanks directly, and he also switched from polyester to alumilite due to how brittle and fragile polyester was.

It was only then that he found out about fountain pens and what they could do. “Pen making ultimately meant making a fountain pen. I made myself use them, because I'm someone who wants to know their product inside and out, so I had to start using a fountain pen. I quickly fell in love.”

If you say “Primary Manipulation” in front of a pen person, they will know exactly what you mean. Brooks named his famous series of resin colors for the process by which they are made. “It’s primary colors being manipulated. There isn’t green in Primary Manipulation, it’s from translucent blue and yellow overlapping.” Constructing such a resin involves knowing, from experience, things like how dye is going to sink through the tube during curing, and how much mixing is enough.

A video Brooks made with David “Figboot” Parker provided insight into the process involved in creating a resin based on a photograph. But Brooks also draws on the element of chance. “New colors come from how disorganized I am in my garage. I have sixty mica powders in stacked jars, and I never put them back in the same place, so I’m constantly seeing new combinations, and then thinking what pouring techniques and contrast colors I should use.” Even mistakes lead to unexpected (or, perhaps, unwanted) success. The “Pastel Primary Manipulation” blanks that became a minor sensation a few years ago were the result of a batch of PM in which not enough drops of dye were added. “It was a mistake I didn’t want to repeat! If I don’t like something, I don’t write the formula down, and then I may have to recreate it later.”

Brooks pronounces himself “obsessed with finding new techniques and design ideas.” “When I’m cooking I’ll think about work, what colors and pouring techniques to use. No matter what I’m doing, the work brain is always churning.”

The brain can, however, be mightier than the hand. Blank making can lead to repetitive motion injuries. “I’m able to break up the day to do blanks half the day and then pens. It’s an advantage of being full-time.” Even worse than the mixing motions is the twisting needed to tighten down the lids of the pressure pots. He spent some time trying to engineer a solution to the pain the process caused to his thumb, and ended up with standard nuts and a low torque impact wrench. When Tim Crowe of Turnt Pen Company was experiencing elbow problems from the same tasks, this solution also gave him some relief.

Repetitive motion stress has caused Brooks to almost entirely quit doing urushi work. “When I was first attending pen shows, the Japanese fountain pens drew my attention and I wanted to know more about urushi. I spent a year doing research – at the time (2014-15) there was almost nothing in English, so I was doing a copy paste of Japanese to Google Translate.” The sanding of tiny areas of pen with tiny pieces of sandpaper was extremely hard on the hands. The cost of gold nibs also became too expensive to justify. While he’s not sensitive to the oils of poison ivy and oak in urushi lacquer, others in his household are allergic, so there was a constant care to avoid contamination with the lacquers. The oils can also come back to the surface with the warming of a user’s hands, especially if the curing process of a pen has been rushed. “I sent a pen for a grind, and the nibmeister proved to be allergic.” Ultimately, “if I did urushi I didn’t have time for anything else.”

As if there was not enough going on in the garage, Brooks has a laser engraver. “That was my COVID phase. I was paying way too much for engraved nibs. And once you show you can do something, someone else will want it. I do still offer custom nib engraving. But lasers are much more affordable now.”

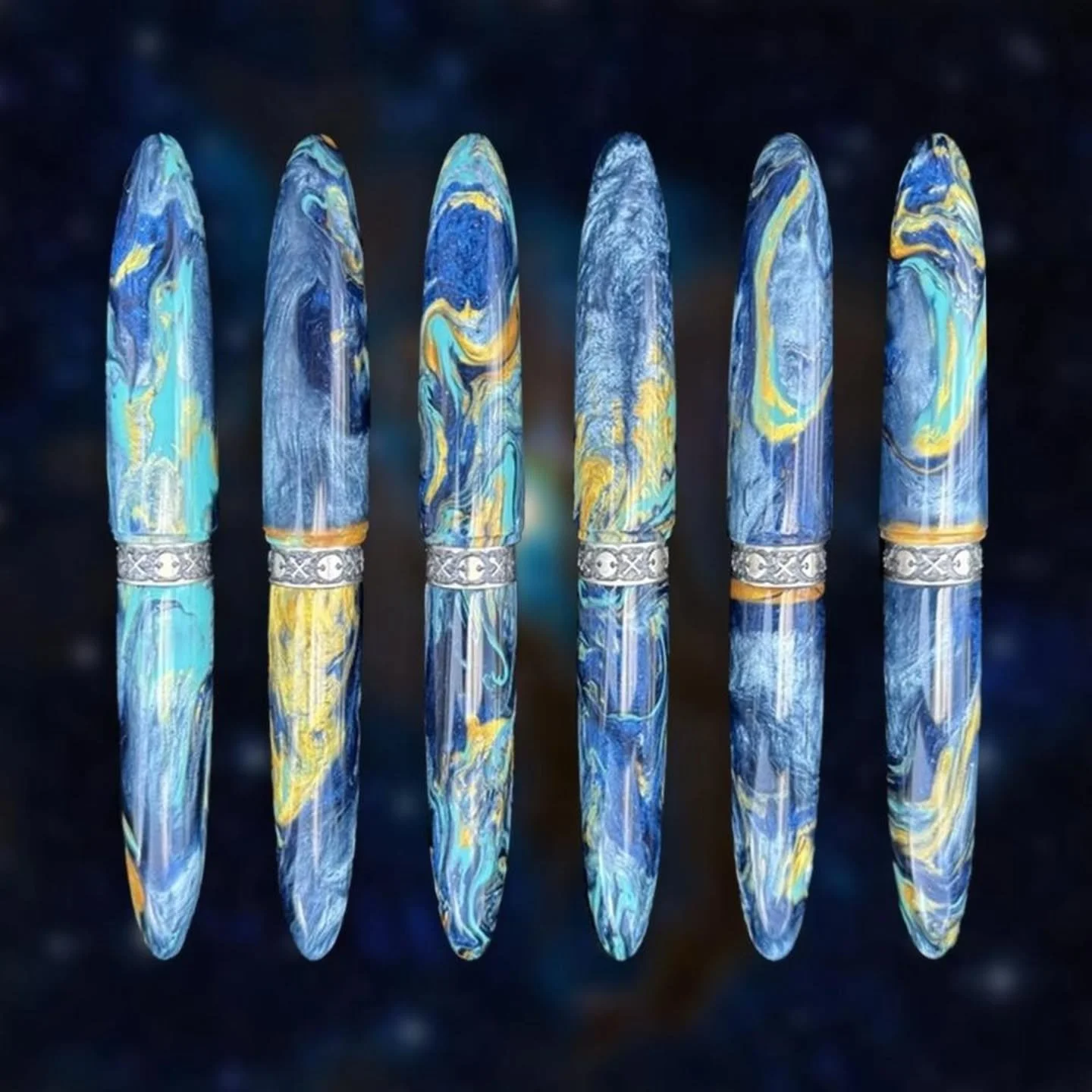

To observers of the fountain pen universe over the last several years, one noticeable trend has been the use by pen “corporations” of hand-cast resins. “Franklin Christoph was one of the first. They would come to my table at shows to discuss options, and the resulting pens would go on their prototype table.” He’s been working for eight years with Leonardo, even before he knew he was. “I got an Instagram message from a friend who said, ‘Check out this Leonardo pen, it looks like someone is copying your stuff.’ It was Calico Koi. I messaged the Leonardo Instagram asking where the material came from, and Salvatore Matrone responded, ‘I bought it from you two years ago.’ That was before Leonardo even existed. At that point I said, OK so do you want any more?” These pens were such a success that other companies began contacting him for resins, and retailers like Atlas, Pen Chalet, and Pen Boutique arranged exclusive pens made by companies from Brooks resins – which are still made by one guy in his garage. “I can do 200 blanks in a day for a corporate order if I have to. I have thirteen pressure pots.” The success of these pens has led pen companies to expand their searches for unique resins from other makers, with Turnt Pen Company, Mckenzie Penworks, and Papa J Studios also creating resins for pens from the larger companies. Brooks himself is working on a set of blanks based on Van Gogh paintings for a Pen Chalet exclusive series, with the specific request that he try to find a way to make the resins reflect the texture of the brush work in the paint. “That’s a very specific direction – I don’t always get that. Usually I’ll get a photo or something else, and they trust me.”

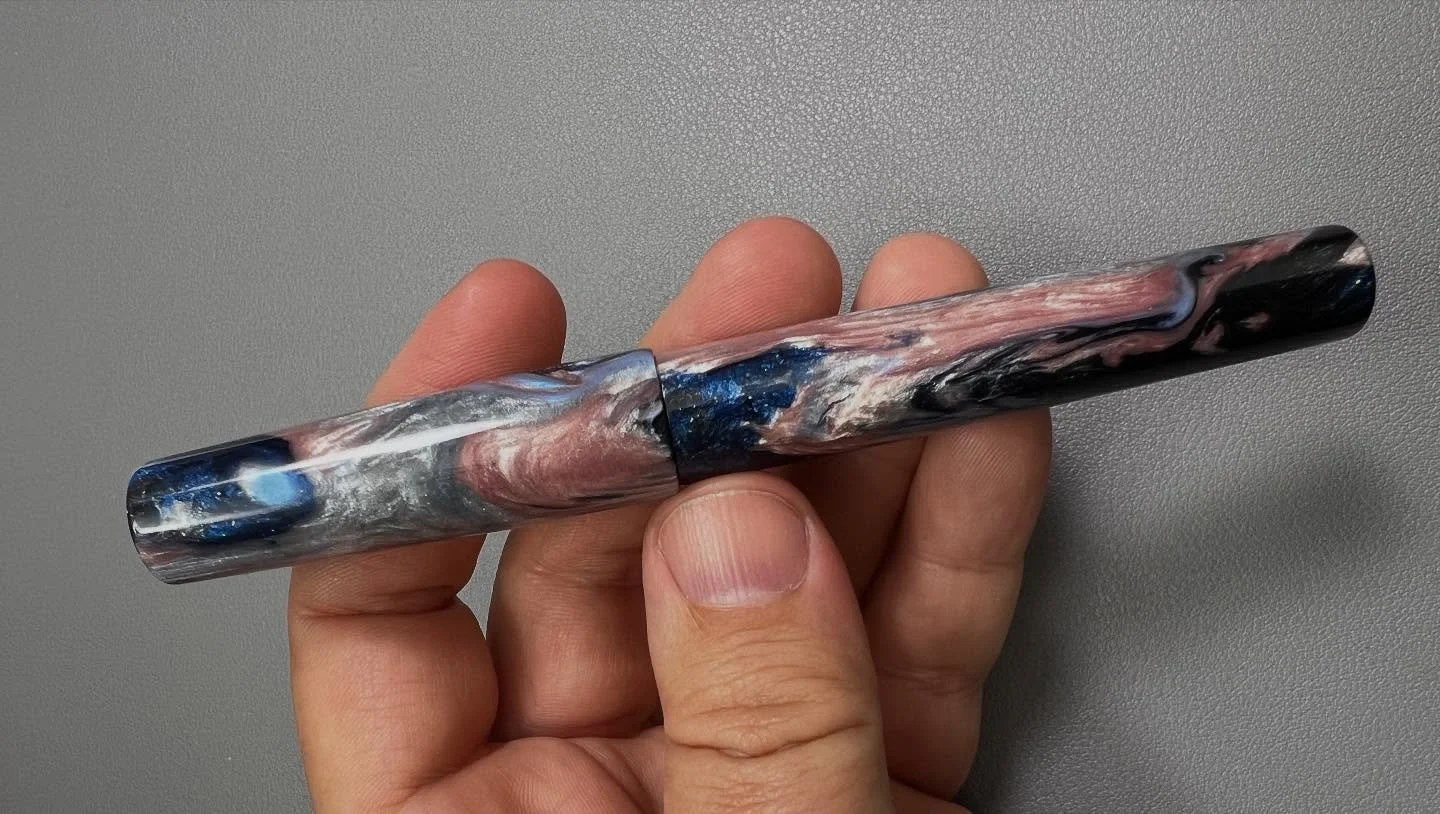

Fans of pens from hand-cast resins know that two pens made from the same blank recipe can look very different, which complicates the process of commissioning a pen because of the variable results. Brooks still does a few commissions, although the wait is somewhat long, and he attempts to mitigate the complexity by making three pens so that the commissioner can choose which one looks most like what they envisioned. A benefit of this approach is that it builds his show inventory.

What pens does Brooks have and love, that were made by other people? He loves his Newton Prospectors, and a pen made for him by Eric Sands (Atelier Lusso) out of a PM material. Not just pens: “I also have a commissioned art print from Shawn Newton, that he was selling to fund his initial equipment purchase, it’s from a photo of Shea jumping one of her horses. It’s hanging over my fireplace.”

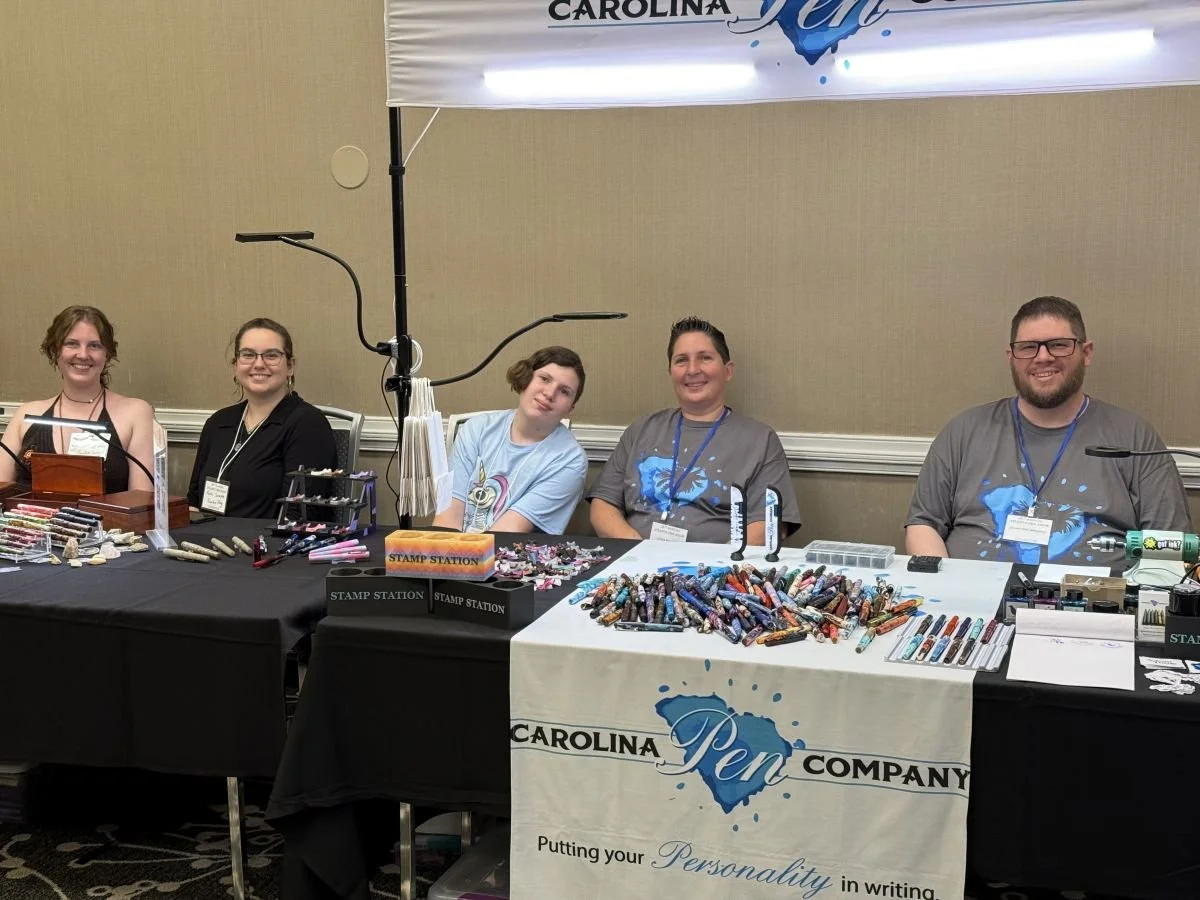

With the boom in fountain pens generally, and independent maker pens in particular, Brooks has become an important mentor for others getting started in pen turning, blank casting, and even the setup of CNC machines for the production of pen parts. He’s a familiar presence at just about every pen show held between February and August, with his table of pens dumped out like a treasure chest. The pen models in his lineup (named after cities in his home state of South Carolina) were inspired by some aspect of a pen he admires, or something customers requested: the conical ends of the Charleston, his first model, are a reflection of the shape of a Nakaya Piccolo; the grip section of the Aiken is based on that of a Parker Duofold. People wanted a cigar shape, or a pocket pen, or something with a clip. The Convert is a pen with two sets of threads inside the section so you can screw in either a rollerball cone or a fountain pen nib unit. “Convert has a dual meaning – you can convert the pen, but also maybe it will convert the one in every crowd who isn’t into fountain pens.” Most recently he’s created the Downtown, to use up some of his vintage celluloid material, adding a clip, and a cap band made from a contrasting material.

Like many independent pen makers, Brooks harbors a little bit of surprise that things have become what they are. “It’s mind boggling how it’s as good now as it was at the beginning.” The explosion of hand-poured resins, and their spread from independent makers to traditional pen companies, has made pen collecting today a different world than it was thirty years ago. There’s a case to be made that it all started in a garage in South Carolina.

Jonathon Brooks’ work can be seen … almost everywhere! On Instagram @carolinapencompany, CarolinaPenCompany.com, and at most pen shows that happen in the US between California in February and San Francisco in August, as well as at Yoseka Stationery Fest.

Enjoy reading The Pen Addict? Then consider becoming a member to receive additional weekly content, giveaways, and discounts in The Pen Addict shop. Plus, you support me and the site directly, for which I am very grateful.

Membership starts at just $5/month, with a discounted annual option available. To find out more about membership click here and join us!